Moving into the new place gave me a chance to update the half-assed method I’d used to hang my original Glass Bead Projection Screen per a comment from a reader that went up on the original makeprojects.com link shortly after the project first published back in 2011. That link’s long dead and unfortunately the comments didn’t survive the transition to the new link on MAKE’s WordPress platform, so I can’t give credit where credit is due. If you were the commenter in question, please do drop me a line and I will update this page accordingly.

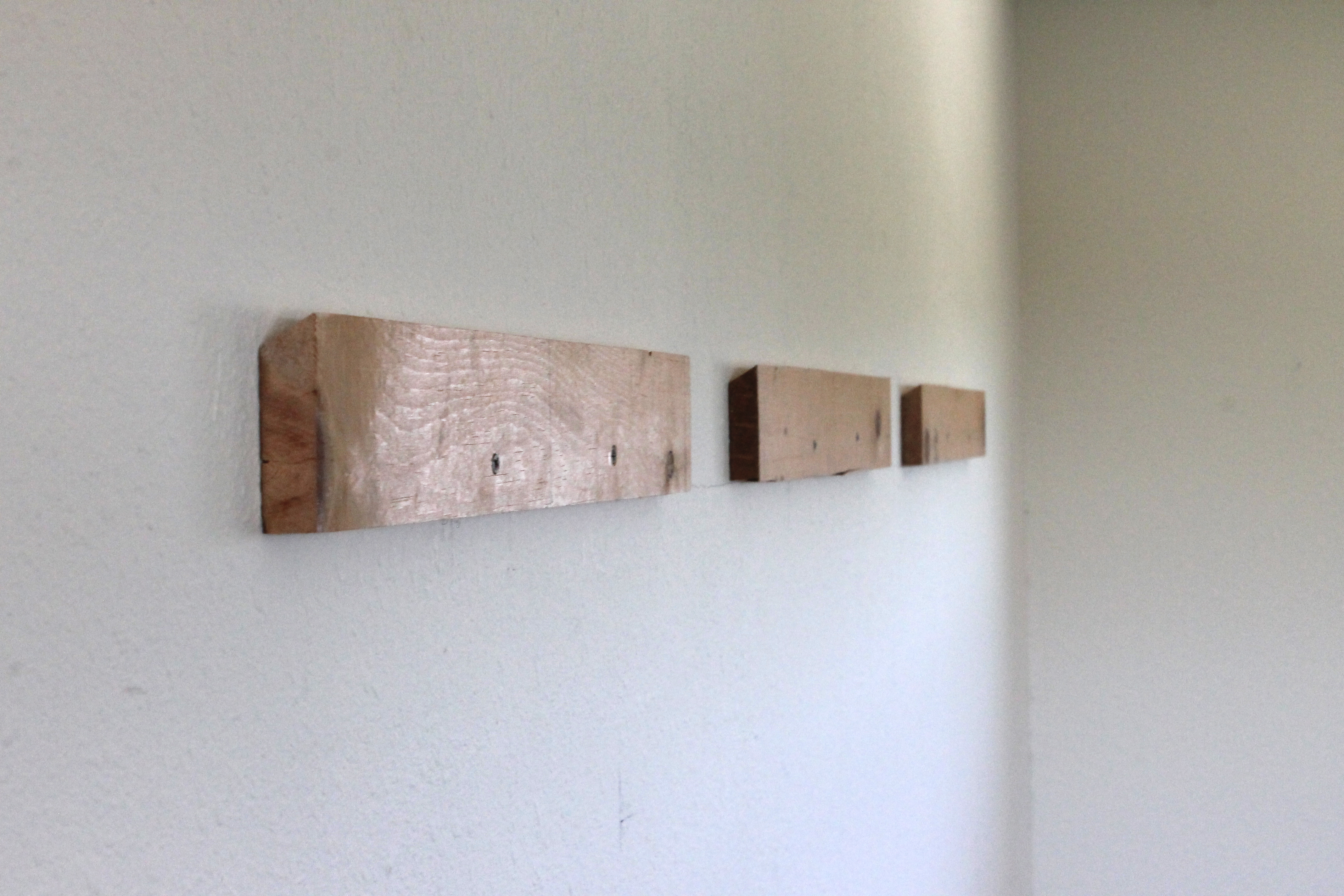

In any case: The suggestion was to hang the screen using a french cleat (Wikipedia), which proved to be a great idea. I ripped the cleat myself on our table saw, and opted for a 30 degree cleat angle. Attaching the cleat to the back of the screen was a bit tricky because of the vertical support members in the screen frame, but I figured out a way to do it by splitting the cleat into three parts. These were first glued to the back of the hardboard screen itself using carpenters glue, then secured with short wood screws that penetrate into the screen but not all the way through. These had to be installed in pre-drilled holes to keep from causing bumps to rise on the screen surface, and the drilling depth had to be carefully controlled to keep from penetrating all the way through. Finally, the cleats were secured to the adjacent vertical frame members, at their upper corners, using short steep corner brackets and their bundled screws.